Our

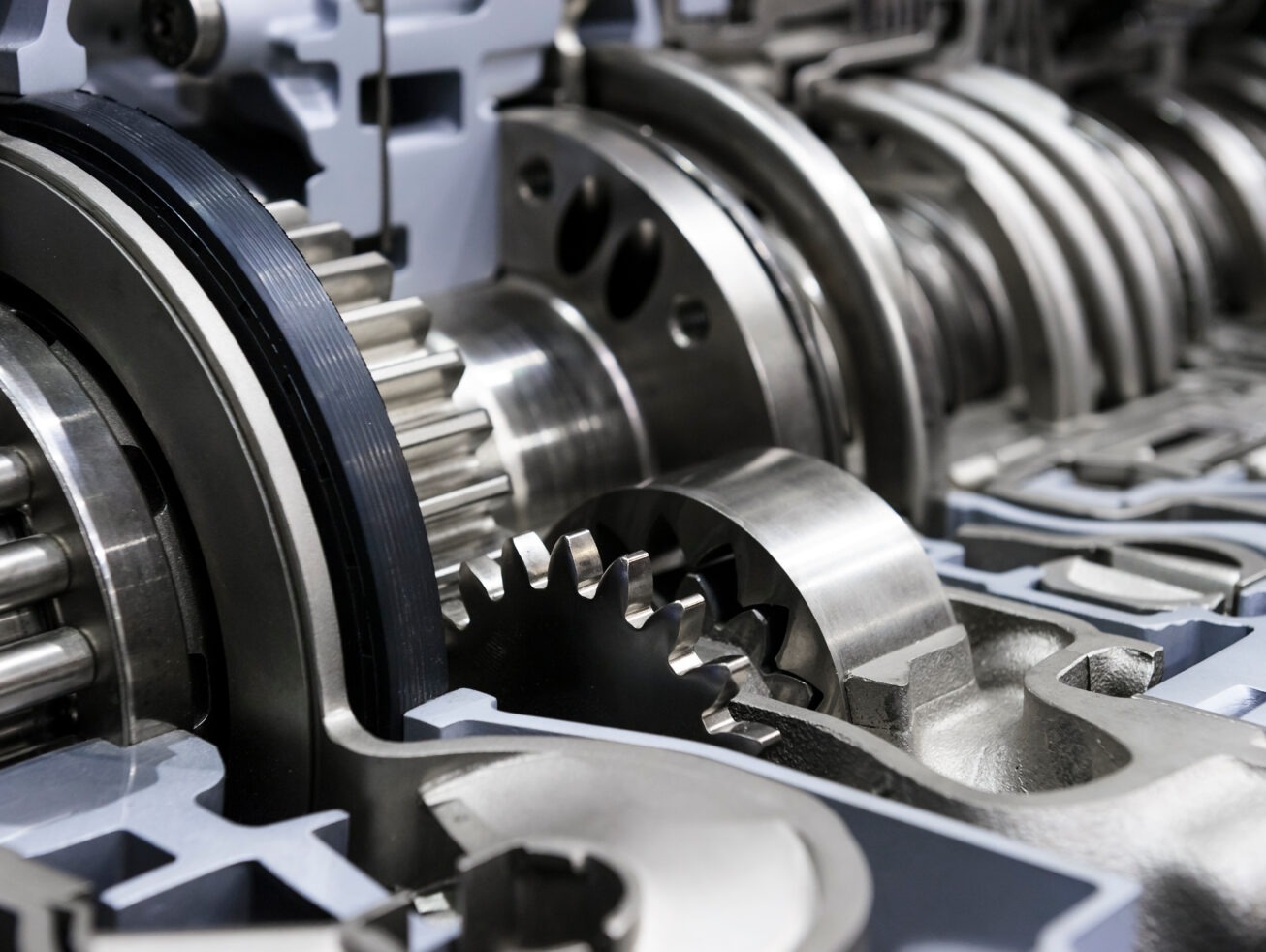

industries

Simply pure:

Pure Steel+

The word “Pure” not only symbolizes the first-class quality of our steel, which is already driving the energy transition and the switch to sustainable mobility. It also stands for the outstanding commitment and performance of our employees, who are driving the transformation process forward with their tireless dedication and are proud to be part of this important project. We use the plus sign to identify our CO2-reduced steel.

Topics that

motivate us

Our

services

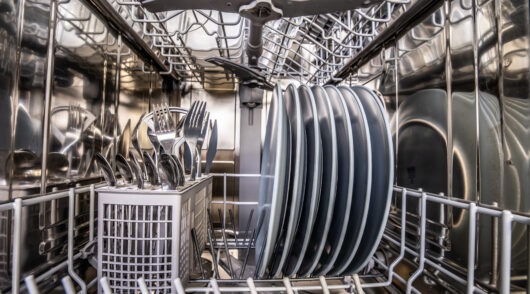

Quality and Testing

Our service includes advising customers on technical issues, ensuring quality in all phases of production and comprehensive testing of all products. We will happily advise you.

Certification and approvals

Find out more about our certificates and approvals, which prove our quality and compliance with industry-specific standards.

Press releases

Get the latest company news and keep up to date with developments and innovations.

Contact

Find the right contact person here.